Industrial Waste Water Treatment-- Reliable Waste Monitoring for Factories

Industrial Waste Water Treatment-- Reliable Waste Monitoring for Factories

Blog Article

Key Methods in Industrial Waste Water Treatment Procedures

The therapy of commercial wastewater is a critical aspect of environmental administration, entailing an array of strategies designed to reduce the effect of pollutants. Innovations in modern technologies such as membrane layer filtration and advanced oxidation processes offer ingenious options for improving therapy effectiveness.

Physical Therapy Techniques

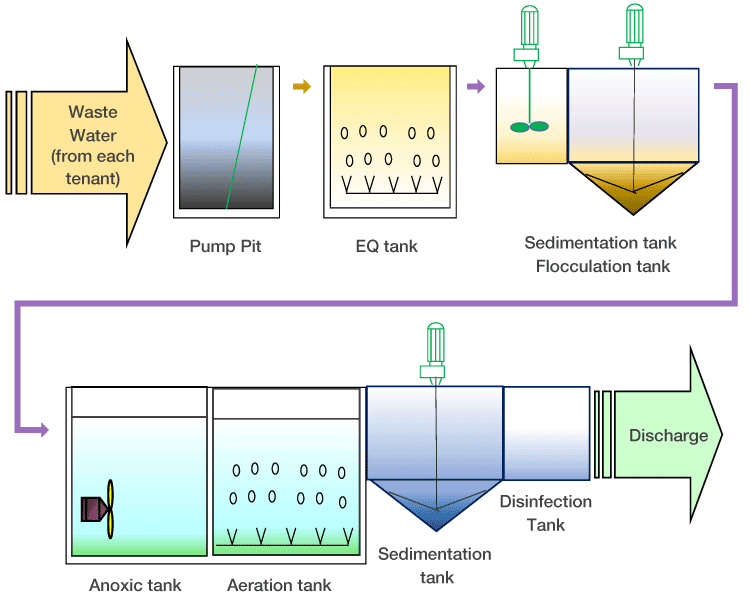

Exactly how successfully can physical therapy techniques attend to the intricacies of industrial wastewater? Physical treatment methods play a pivotal duty in the initial phases of wastewater management, concentrating mostly on the removal of solids and large particulates. Techniques such as filtering, flotation, and sedimentation are vital for lowering the focus of put on hold solids, therefore boosting the performance of subsequent treatment processes.

Sedimentation entails the gravitational settling of solids, enabling for the separation of much heavier materials from the wastewater. This technique is particularly reliable in clarifying water prior to chemical or biological therapies.

Additionally, flotation approaches, which use air bubbles to raise suspended solids to the surface area for removal, work in treating wastewater with high focus of fats, oils, and oils. In general, physical therapy methods work as a critical primary step in the thorough management of commercial wastewater, making sure that the load on subsequent therapy phases is reduced and boosting overall treatment efficiency.

Chemical Treatment Methods

While physical therapy methods prepared for efficient wastewater management, chemical therapy strategies are essential for resolving the a lot more complex impurities typically located in industrial effluents. These approaches use numerous chemical agents to speed up, neutralize, or oxidize unsafe substances, making certain a more detailed removal of toxins.

One common technique is coagulation and flocculation, where chemical coagulants such as aluminum sulfate or ferric chloride are contributed to advertise the aggregation of suspended fragments. This process improves solid-liquid splitting up, reducing turbidity and enhancing water top quality. Additionally, neutralization procedures are used to adjust the pH of wastewater, utilizing bases or acids to neutralize acidic or alkaline streams, respectively.

Oxidation-reduction reactions play a critical role in degrading organic impurities and virus. Chemical oxidants like chlorine, hydrogen, or ozone peroxide are used to damage down intricate natural compounds, making them less hazardous or a lot more biodegradable. Progressed oxidation procedures (AOPs) incorporate numerous oxidation strategies to boost toxin elimination performance.

Organic Therapy Procedures

The performance of wastewater therapy is significantly enhanced by organic treatment processes, which harness the natural metabolic activities of microorganisms to decompose raw material and get rid of toxins. Industrial Waste Water Treatment. These procedures mostly include cardiovascular and anaerobic digestion, each customized for details sorts of wastewater

Cardiovascular treatment processes make use of oxygen to sustain microbial growth, promoting the failure of natural contaminants into co2 and water. Usual techniques include turned on sludge systems, where oygenation storage tanks facilitate the blending of wastewater with bacteria, and trickling filters, which encourage biofilm growth on media surfaces.

Conversely, anaerobic therapy processes take place in the lack of oxygen, utilizing anaerobic microorganisms to disintegrate raw material, leading to biogas manufacturing, a renewable resource resource. Anaerobic digesters are typically utilized in commercial setups for this purpose, successfully minimizing the quantity of sludge while producing use this link valuable biogas.

The option of a biological therapy method relies on wastewater qualities, therapy goals, and governing standards. The assimilation of biological procedures in wastewater therapy not only boosts pollutant elimination efficiency however additionally promotes sustainability by lessening chemical usage and supporting source recovery.

Advanced Oxidation Processes

Typical AOP techniques consist of Fenton's photocatalysis, ozonation, and reagent. Fenton's reagent, a mix of hydrogen peroxide and ferrous iron, catalyzes the development of hydroxyl radicals, making it effective for treating wastewater having phenolic compounds and various other recalcitrant materials. Ozonation utilizes ozone as a powerful oxidant, with the ability of weakening a large range of organic contaminants while simultaneously sanitizing the effluent. Photocatalysis employs light-activated drivers, such as titanium dioxide, to boost oxidation reactions and get rid of impurities.

AOPs offer a number of benefits, consisting of reduced sludge production and the capability to deal with wastewater with high focus of organic pollutants. The implementation of AOPs requires careful consideration of operational parameters and cost-effectiveness, guaranteeing that these sophisticated methods are properly integrated into existing wastewater treatment systems.

Membrane Filtration Technologies

Microfiltration is reliable for removing put on hold official source solids and microorganisms, while ultrafiltration targets smaller sized natural molecules and viruses. Nanofiltration connects the gap in between ultrafiltration and turn around osmosis, efficiently removing natural substances and divalent ions. Reverse osmosis gives the highest possible level of purification, used primarily for desalination and eliminating mono-valent ions.

Membrane technologies supply numerous benefits, consisting of reduced power intake contrasted to typical therapy approaches, modular layout for scalability, and the possibility for water recuperation and reuse. Difficulties such as membrane fouling and the need for normal upkeep need to be dealt with to guarantee system efficacy. Overall, membrane layer filtering innovations represent address a vital part of modern commercial wastewater treatment methods, promoting sustainability and resource preservation in water monitoring.

Final Thought

In verdict, commercial wastewater treatment employs a varied variety of strategies, consisting of physical, chemical, biological, and progressed methods. Each approach plays a crucial function in successfully dealing with different pollutants, enhancing water top quality, and advertising resource sustainability. The assimilation of these methods cultivates a comprehensive therapy technique, ensuring that commercial effluents satisfy regulatory requirements while reducing ecological impact. Proceeded developments in these techniques will better enhance the performance and efficiency of wastewater treatment processes in commercial setups.

The therapy of industrial wastewater is a vital facet of environmental management, including an array of strategies designed to reduce the effect of impurities.How efficiently can physical treatment techniques attend to the intricacies of commercial wastewater?Advanced oxidation procedures (AOPs) represent an advanced technique in commercial wastewater therapy, made to effectively degrade organic pollutants that are typically immune to traditional therapy techniques (Industrial Waste Water Treatment).In verdict, commercial wastewater treatment utilizes a varied selection of methods, consisting of physical, chemical, organic, and progressed approaches. Proceeded innovations in these techniques will certainly better boost the performance and performance of wastewater therapy procedures in industrial settings

Report this page